Episode 2

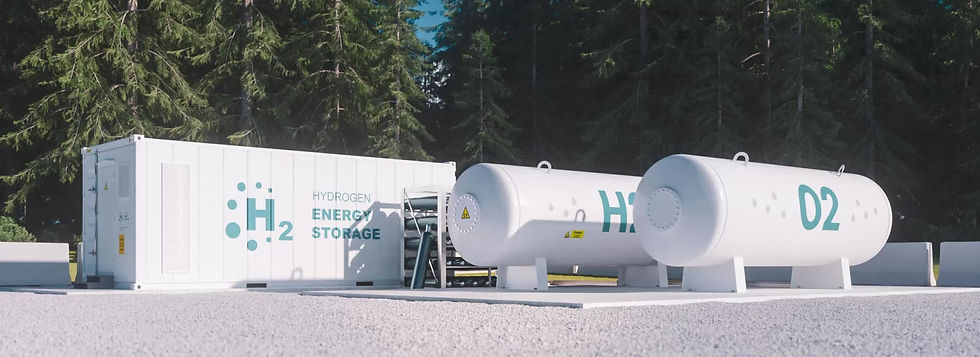

HYDROGEN

STORAGE & TRANSPORTATION

Green hydrogen is a good storage and carrier medium for renewable energies. In particular, for wind and solar power, both of which are dependent on weather fluctuations. Energy generated during windy and sunny periods needs to be stored for future use. Because green hydrogen consumption is not limited to the areas where it is produced, it is suitable for storage and transportation to where it is needed. However, meeting demand requires high-capacity facilities.

The requirements for storage and transportation of hydrogen are:

Storage and transportation at high energy density

Storage and transportation without energy losses

Safe storage and transportation

There are various options available for storing and transporting hydrogen and more are being developed. This is because there is no perfect solution as each technology is based on the needs of the end user and travel distances.

Where they are the same is that all processes require the exchange of thermal energy,

which is why heat exchangers play an essential role.

PURPOSE

Renewable energies are versatile.

CHALLENGES

Hydrogen has a volumetric energy density being 3.2 times lower than natural gas and 2,700 times lower than gasoline.

Hydrogen is not necessarily consumed where it is produced.

Big storage and transport capacities necessary for H2.

Hydrogen distribution and transport is challenged by its low volumetric energy density.

For the storage of hydrogen to be economically viable, its storage density must be increased!

HYDROGEN COMPRESSION & COMPRESSED STORAGE

Compressed H2 is the most matured and relevant of the physical storage options. As well as hydrogen gas storage vessels and pipelines, compressed H2 can be blended into the natural gas grid, injected into the grid after methanation and be stored underground.

Compressors are an essential component in the value chain of green hydrogen to increase pressure, density and energy content per volume. Compressor systems require heat exchangers to cool hydrogen between single compression stages and after compression.

Primary Energy

Transportation & Distribution

Conversion &

Processing

Final Energy

Demand

Storage

Ammonia or LOHC Tanker

Tube Trailer

Tube Trailer

H2 Storage Tank

Refinery

Biogas

Renewable Energy

Electrolyser

Power Plants

Cavern Storage

Grid

Fuel Cell

Domestic Home

Industry

Commercial

Power Plant

Pipeline

Hydrogen Fuel Station

Heat exchangers in H2 compressor systems are normally designed as shell & tube units, as the round shape is by nature

well resistant to pressure and pressure load changes.

Kelvion Double Tube Safety Heat Exchangers offer additional reliability and safety as well as the simplification of the

plant setup handling the small molecule H2, where material embrittlement, permeation and leakages must be taken

into account with high sensitivity.

COMPRESSED STORAGE

COMPRESSOR

HALL

HIGH PRESSURE

H2 TANK

Hydrogen from Electrolyzer

First

Compression Stage

Second Compression Stage

Water

Separator

Hydrogen

Tank

Aftercooler

Intercooler

COMPRESSED HYDROGEN STORAGE AND TRANSPORTATION APPLICATIONS

Tank Storage

Cavern Storage

Train Transportation

Tube Trailer

FOCAL-POINT: SAFE HEAT EXCHANGE IN HYDROGEN GAS STORAGE & TRANSPORTATION

Storage and transportation are important stages in the value chain of green hydrogen as it allows energy generated by renewables to be saved and also made available in locations without renewable energy generation. Compressing hydrogen and increasing its density is an efficient method of storing and transporting it and is widely applied in, for example, tank storage, cavern storage and transportation by truck or pipeline.

Hydrogen as a compressed gas can be one main element in the energy transition. But, at the same time, the properties and characteristics of H2 are challenging, particularly with regard to safety

READ MORE and DOWNLOAD OUR TECH-PAPER

PIPELINE TRANSPORTATION & GAS COMPRESSION STATIONS

When hydrogen is blended with natural gas, up to 20%, it is possible to transport it via existing pipelines without major equipment adjustments. Concentrations above this require more substantial modifications.

As the technologies for achieving this already exist, it makes converting gas infrastructure a more

economical and convenient solution than building special hydrogen pipelines.

The gas pressure and flow to the consumer is maintained by compressor stations in the pipeline network.

CHALLENGES FOR H2 PIPELINE TRANSPORTATION

Risk of Leakage

Low density of H2 requires more compression

H2 has lower heating value than NG > Adjustmemt of the supplied gas is required

H2 TRANSPORTATION IN EXISTING NATURAL GAS PIPELINES

As mentioned above, when hydrogen is blended with natural gas the current infrastructure can cope.

Hydrogen has a smaller density than natural gas so, the higher the concentration of hydrogen in the blend, the lower the density of the blend. As a result, the compressors are not powerful enough and need to be refurbished or replaced.

On the plus side, this will cost significantly less than building dedicated hydrogen pipelines.

The compressor can generally continue to be used without major changes.

The compressor housing can be maintained, impellers and feedback stages as well as gears must be adjusted.

The compressor must be replaced.

Up to approx.

10% H2

Up to approx.

40% H2

From approx.

40% H2

Compression equipment of a hydrogen pipeline, including the drives, would be about three times the cost of a natural gas pipeline.

LOHC

LIQUID ORGANIC HYDROGEN CARRIER

Hydrogenation & Dehydrogenation

LOHCs absorb hydrogen by forming chemical compounds. Storage can take place under ambient temperatures and pressures in conventional tanks.

Currently the LOHC energy density is 25% of that for diesel. In other words, 1 liter of diesel equals 4 to 5 liters of LOHC+. Also, LOHCs only have a loading capacity of ~ 6 % per mass.

The loading cycle, called hydrogenation, is an exothermic reaction so heat is released. To use the H2 after storage and transport, it must be unloaded again from the LOHC (dehydrogenation) by putting energy into a reactor at ~300°C. Again, this step needs heat input so the overall efficiency from H2 production to H2 is also strongly dependent on where the heat comes from and if the waste heat from hydrogenation is reused elsewhere.

PRINCIPLE

LOHC+

H2 Production

Hydrogenation

LOHC-

H2 Transport

Dehydrogenation

H2 Utilization

As LOHCs are recovered rather than consumed during the process, transportation by using LOHCs has no impact on CO2 emissions. By far the biggest advantage is that existing infrastructure, including pipelines, tankers, trucks and trains, can be used to transport hydrogen in LOHC+.

The drawbacks to this approach are the transportation of non-loaded LOHC to a location where it can be hydrogenated and reduced overall efficiency, as parts of the transported hydrogen are required to fuel the reactor.

HYDROGENATION LOHC+

DEHYDROGENATION LOHC-

Liquid

Liquid

Hydrogen Recycle

Air Cooler

Air Compressor

Air

Hydrogen

Pressure Swing

Absorption

Hydrogen

to Fuel Cell

LOHC-

Tank

LOHC+

Tank

LOHC+

Heater

LOHC+

Cooler

Waste Heat

Recovery

Exhaust Gas

H2 Preheater

Gas

Burner

HYDROGEN DISTRIBUTION

HYDROGEN REFUELING STATION

Also used as interstage high pressure cooling for H2 compressors

Compressor

Compressor Booster

Chiller

Mid Pressure Buffer Storage 900 bar

Car Onboard Tank

Compressor

Mid Pressure Buffer Storage 500 bar

Dispenser

K°BOND PERFORMANCE AND FOOTPRINT

K°BOND - WHAT IS INSIDE?

Straight and zig zag

micro-channels

Channels of

~ 1- 3 mm height &

~ 2 – 6 mm width

Welded Header for

media supply